Making Sense of Industrial Data

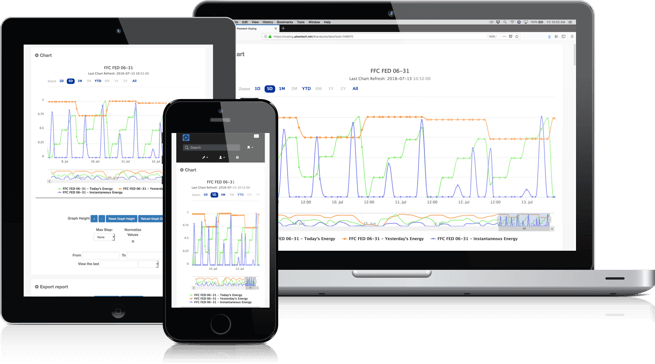

Welcome to OnPing – the home for industrialized automation solutions. Our fully integrated Edge/Cloud infrastructure forms a bridge between operations, technology, and people – allowing information to flow freely through an organization. Connect to devices, manage data, operate controls, and develop regulatory reports in one space.

Automation in Industrial Manufacturing

Modern industrial processes are designed for maximum efficiency. Companies spend millions for process engineering, implementation, and data collection in efforts to minimize inputs and maximize outputs. For many manufacturing organizations, automation is the Holy Grail of efficiency.

OnPing’s data and device management tools are developed from the ground up based on experience in the field. We develop practical features to solve real problems. Many water and wastewater treatment facilities face similar issues, especially in rural areas! Many of these probably sound all too familiar:

- Sites are spread out

- Mixed assortment brands and generations of equipment

- Existing hardware and software are outdated and constantly fail

- Bad internet connection and cell service limit options

- Good people are hard to keep around

- Understaffed, overworked, and don’t have time to look through a thousand new products

- Small facilities and a small staff with no ‘technical’ experts

This list could go on forever, but the basic message is, “Do more with less.” Distance and reliability issues come with the territory, and most municipal districts see no end to these traditional rural and small town obstacles. These problems often seem impossible to solve with the annual budget, so the issues get marked down as ‘just part of the job’ to suffer through.

Enter, OnPing.

How Can OnPing Help?

Connectivity and Compatibility

First things first, get connected! Enabling OnPing connections in your facility starts with connecting to the internet. Cellular networks, local internet connections, radio connectivity, and even new satellite internet services are ways enable OnPing access in your facilities. Even the most far out rural locations can be brought online by using the right set of technologies.

If there is any doubt about which equipment can be connected, give us a call. Often, we visit sites that were assumed impossible to connect to, only to find out the current hardware had the capabilities but technicians simply weren’t aware of a feature or the connections just weren’t being used.

Another hesitation we see regarding connectivity is found in a lot of older facilities with legacy equipment. It’s easy to assume older equipment, mismatched models sets, or equipment manufactures will be difficult and expensive to connect to. However, OnPing works with any device or communication protocol. Sometimes, a simple sensor or drive is all that needs to be added to begin collecting information from a system.

Automation improvement is too often thought of in terms of limitations and equipment upgrades or migrations – and the big price tags that follow. Instead, OnPing is about getting the most out of what you have. Before you start upgrading hardware, make sure you are getting the most value possible from the current setup.

Platforming Automation

What is a platform?

The basic idea of a platform is this: Instead of promising a single tool that can do every job, we built a place to put the tools – like a giant virtual toolbox or automation warehouse. If you can access OnPing, you can start working with all of those tools!

Data gathering, system control, alarming, compliance and administrative reporting, remote telemetrics, application development, system access management, over the air software updates, and a host of other important automation tasks can be handled in the OnPing cloud environment. Lots of people interact with an automation system and need many different resources to do their job. OnPing brings everyone and everything into the same place. Then, we make sure the best tools are available for any job, always.

The Layers of OnPing

The framework of OnPing is its strength, providing a robust communications infrastructure for monitoring, system controls and alerting. We visualize this structure in layers:

Dashboarding Tools create and distribute data in the way that best makes sense to you. Unlike many dashboard systems (tableau, Power BI, etc) data signals can flow 2 ways, enabling application loops.

Scripting and Reporting Tools organize and batch data on the fly, as well as incorporate a full power scripting system to create new metrics from existing ones and to conditionally automate system actions.

Data Ingestion Tools include drivers for legacy and cutting-edge systems. This tooling also includes proper low bandwidth telemetry control.

Lastly, we include tools for Store and Recovery and Edge Device and Application Management.

All of these layers can be configured in numerous ways to allow OnPing to fit in to nearly any ecosystem or facility. Give us the problem, and let us put the right tools to work for you.

Continuous Improvement

We understand there will always be a new, ‘next big thing’. We keep up with the cutting edge of automation technology and are frequently releasing new features or feature updates. Stay in touch with our updates by following the OnPing blog or checking out the bi-monthly OnPing newsletter.

Importantly, there are never any modules to add on or features gated behind premium areas in the platform. When you get OnPing, you get OnPing! Every update comes included. No more buying expansion modules or running into premium walls mid-task.

Reliability

There are a lot of things that cause frustration with legacy systems, but none so much as problems with reliability! An unreliable system is worse than the new trainee that keeps trying just a little too hard to do a little too much. The trainee affects a few people – a poorly plant automation system often impacts everyone!

Unreliability is a catastrophic issue. If you can’t trust the data you get, or that you will have data, then the information in the system is worth less than nothing.

OnPing Puts Reliability First

OnPing makes data integrity a top priority, and it starts at the ground level with the Lumberjack.

Lumberjack Edge Computing System

The first role of the Lumberjack is to make communications work between OnPing and other devices. Every data stream in OnPing originates in a Lumberjack. When we say we can work with any device or protocol, it is because the Lumberjack standardizes all the data before it gets to the OnPing cloud space.

The Lumberjack is vital to how OnPing works, at it also makes the platform a great fit for water treatment facilities. We can bring in data from facilities with a mix of old and new equipment, from any number of manufacturers, then make it work together in OnPing because it all looks the same when it gets there. This is a huge benefit in the industry, because it means upgrading your data system doesn’t require a full scale upgrade of the hardware!

A second, key way the Lumberjack serves OnPing is as a data logger (hence, the name “Lumberjack”). Logging is important, because in the case of network disruption it offers OnPing a way of maintaining an unitterupted, pure data set. When connectivity is regained, the Lumberjack and OnPing cloud synchronize data – so you are never left in the dark. Our fully integrated Cloud/Edge environment supports Users who need to trust data and make decisions quickly. No where is the more important or apparent than for the peoople that manage our water supply.

Cloud/Edge Integration

Where other cloud-based solutions compromise data integrity for ‘flexibility’, we see the edge and cloud as two parts of a whole. The relationship between Lumberjack, LAS, and OnPing integrates edge and cloud systems in a single platform where Users can experience the best of both worlds – flexibility to do what you want with good, reliable data.

In practical terms, data ingestion, communication, and archiving occur near the source where data can be retrieved and handled most reliably. Edge handling of these processes preserves data integrity and mitigates corruption caused by inevitable network interruptions. Data is collected on the ground, harmonized in a consistent record of events and then pushed to the cloud where it can take advantage of OnPing’s suite of tools.

Versatile, by Design

OnPing facilitates versatility through simplicity. We have three data centric goals – Make data accessible; Make data make sense; and Make data easy to use. Each of these is accomplished by simplifying some part of the automation process.

For example, OnPing’s integrated edge/cloud infrastructure (managed by the Lumberjack and Lumberjack Application System) naturally supports a highly accessible and intuitive data system. Low-code tools, referred to as Widgets, then enable Users to easily utilize data in OnPing. Widgets are building blocks that offer basic solutions to common tasks. Experiment with different combinations of building blocks to create powerful tools and build advanced automation structures.