OnPing Can Now Provide Full Plunger Lift Control and Optimization

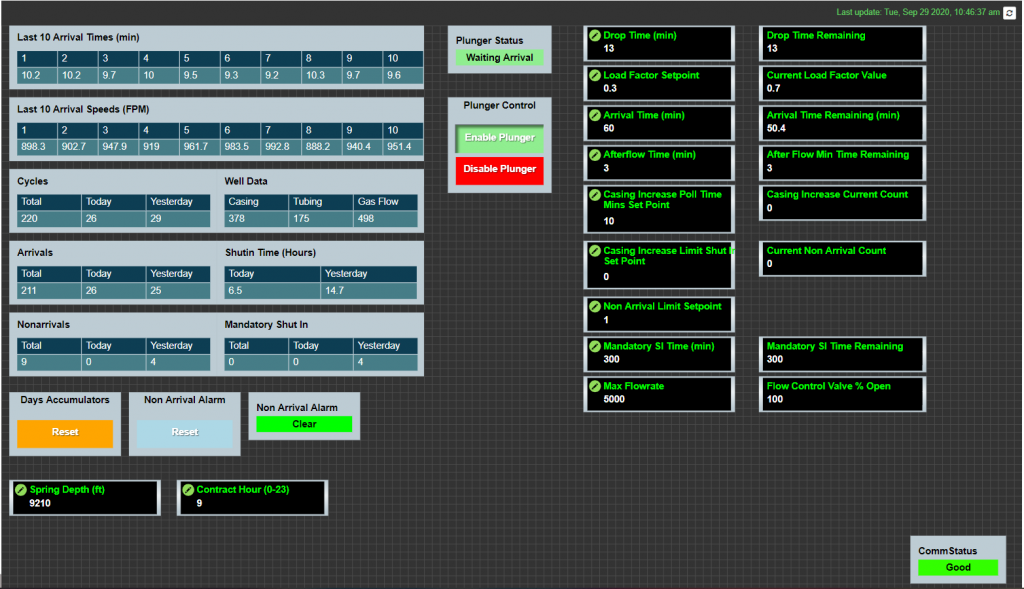

OnPing along with the skilled field staff at Plow Technologies has been working hard to optimize an advanced plunger lift control application, controllable and viewable from any device via OnPing. This new Plunger Lift System is now live on several sites and we’re getting great results from it. Our HMI serves as the control center for this application, providing up to the minute data on arrivals, speeds, cycles, shut in times and more, as well as controls, setpoints and alarm statuses. Contact us about creating a Plunger Lift tool specific to your sites.

The current programs deployed features are optional and can be changed, removed, or disabled if not wanted or needed:

• Remote Plunger Enable / Disable – This starts the normal plunger cycle or stops it.

• Arrival Time Setpoint – Gives a determined amount of time for the plunger to arrive.

• Drop Time Setpoint – This is the amount of time given to the plunger to drop to bottom before the valve comes back open for another plunger cycle.

• After Flow Time Setpoint – This allows the valve to stay open for an allotted amount of time after the arrival of the plunger.

• Non Arrival Limit Setpoint – This setpoint determines the number of non-arrivals allowed before a mandatory shut-in.

• Mandatory Shut In Setpoint – This determines the amount of time a mandatory shut-in lasts before resetting and going back to a normal plunger cycle after hitting non arrival limit.

• Secondary Mandatory Shut In Setpoint – This determines the amount of time the second mandatory shut-in lasts before resetting and going back to a normal plunger cycle if set. This allows for additional time to be shut in if after the first Mandatory Shut you receive another non arrival.

• Casing Increase Time Setpoint – This is the time interval at which the program compares the casing pressure to its previous reading.

• Casing Increase Shut In Limit Setpoint – This is the number of times the casing is allowed to increase during the after flow based on the casing increase time setpoint. Once the limit is met the well will shut-in for a normal drop time before starting a new plunger cycle.

• Load Factor Current Value – This is the load factor calculated from Casing, Tubing, and Static pressure.

• Load Factor Setpoint – This allows for a condition to be met in normal operation and mandatory shut in that lets the plunger cycle start or start early. For normal operation, if drop time is met and the load factor current value is less than this setpoint the plunger cycle will start. For mandatory shut-in, if the drop time is met and the load factor current value is less than this setpoint the mandatory shut-in setpoint will be skipped and a normal plunger cycle will start.

• Valve Control Setpoint – This allows a valve to be throttled back and maintain a setpoint can be anything brought into the program (Flow Rate, Tubing, Differential, ext.).

• Remote Force Open – This bypasses all control and forces control valve to stay open until disabled.

• Plunger Distance Traveled – This Is the distance of your plunger based off of the spring depth and number of cycles the well has done since Installation. This allows for maintenance monitoring of the plunger’s life cycle. Can be set up to notify you when plunger has reached a high mileage of travel and needs replaced. Can be set to any form of measurement.

• OnPing Plunger Auto Optimization – This Is an OnPing feature that allows the Plunger Lift Control Application to auto adjust itself based on setpoints set by you. This will Increase or Decrease the amount of time allotted for after flow based on arrival times.